Cryogenic Breakaway Couplings

Overview

The implications of a driveaway incident on a cryogenic application can be very serious. Not only is there a risk of cold burns from the liquid and gas, but there are also other serious risks such as that of fire damage and explosion resulting from the uncontrolled release of oxygen and asphyxiation of personnel resulting from the depletion of oxygen levels in the boarding area produced by the release of gases such as nitrogen.

Our cryogenic breakaway couplings can help reduce the risks associated with driveaway incidents and provide peace of mind for your business and your employees.

APC have comprehensive on-site oxygen cleaning facilities to ensure that the couplings are supplied in the ultra-clean condition demanded by all industrial gases companies. Inspection is carried by ultraviolet light to expose any evidence of moisture, oil, grease, cleaning agents, flux or any other matter that may be present. All cryogenic breakaway couplings are rigorously pressure-tested with nitrogen gas prior to tagging, packaging and despatch.

How it Works

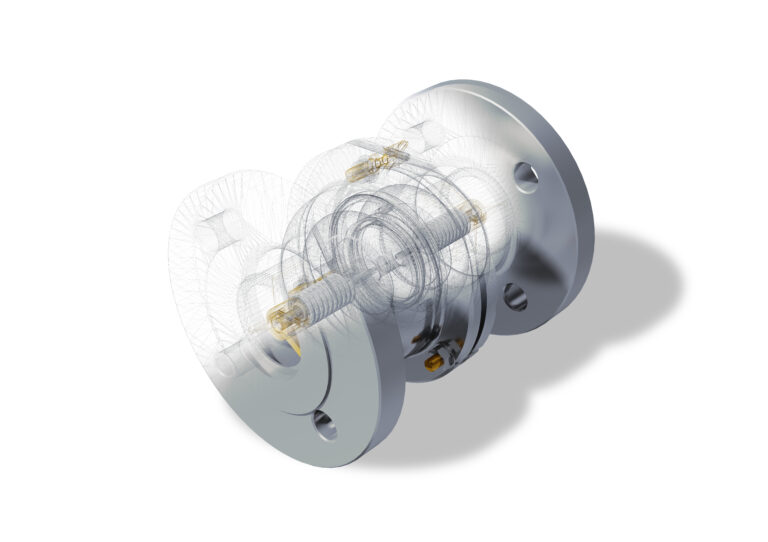

The breakaway coupling is normally flanged onto the terminal pipe-work at one end and at the other end to a flexible loading hose, allowing free flow of product in both directions.

During a driveaway or towaway incident, the flexible loading hose comes into tension, transmitting the load to the breakaway coupling which causes the pre-determined break bolts to snap, allowing the coupling halves to separate.

When the safety breakaway coupling is employed, each half of the coupling seals immediately, preventing major product spillage.

Benefits

Reliable operation

Positive shut off

Proven design

Accuracy

Unique break bolt design

Bespoke

Range of applications

Rigorously tested

Obtainable records

Spare parts

Product trials

Manufacturing quality

Manufactured to the Highest Quality Control Standard - QA system ISO 9001 2015 approved.

CE marked to PED 2014/68/EU

Cryogenic breakaway couplings applications:

- Road tanker loading and unloading

- Rail tanker loading and unloading

- Process product transfer.

Products handled include:

- Liquefied gases: LNG, liquid oxygen, liquid nitrogen, liquid argon and liquid carbon dioxide.

- Sizes

1″ to 4″ or metric equivalents. - Main body construction

Standard material: stainless steel 316. - Connections

Threaded and flanged variations, 1 1/2″ to 4” to most standards including ANSI, BS, DIN, ISO and JIS. - Seals

- Bespoke

Break bolts calculated to suit each individual application. - Design

Coupling designed for bi-directional flow. - Temperature range

-196˚C to 100˚C.

Enquire Now

To discuss your project, contact one of our team today.

- 1 Brindley Road, South West Industrial Estate, Peterlee. Co.Durham. SR8 2LT

- +44 (0) 191 518 1555

- sales@alphaprocess.co.uk