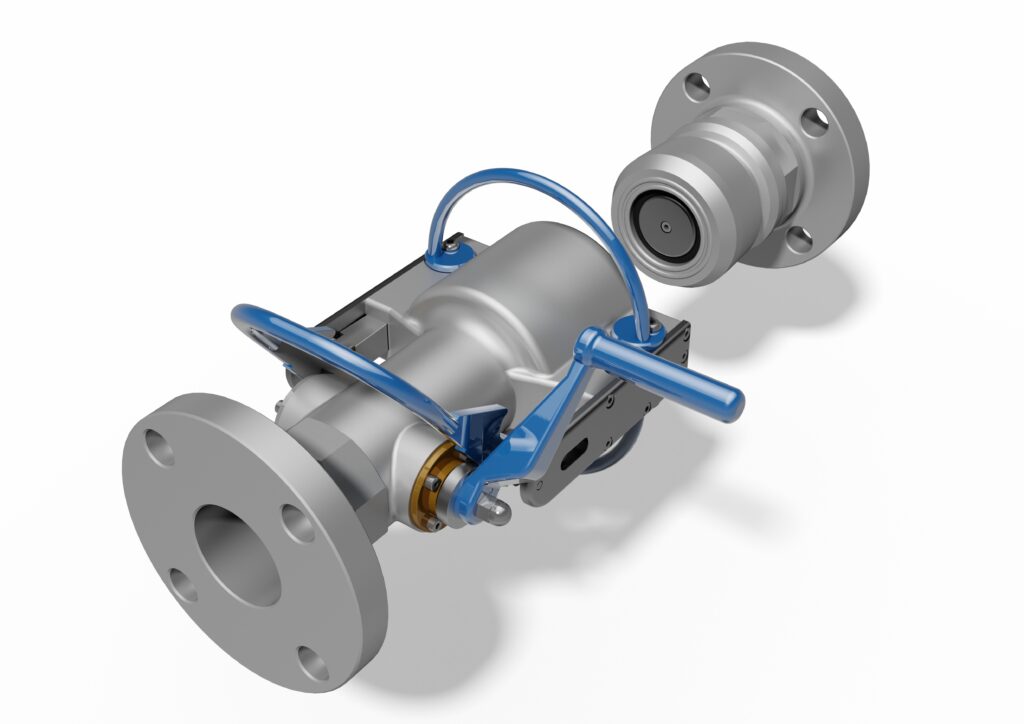

Fluiseal Drybreak Coupling

Overview

The Fluiseal drybreak coupling is well proven with over 30 years’ field service and is used by many of the world’s major oil and gas companies.

The simple operating procedure provides quick and safe connection, with rapid tanker turnaround and improved operator efficiency, No hammers are required to tighten coupling, and there are no threads to wear. You can create a pressure tight connection in under 10 seconds.

Benefits

Consistent

Fully interlocked design

Damage resistant

Efficient

Complete ability

High strength

Easy to use

Reliable operation

Life span

Range of applications

Rigorously tested

Product trials

Obtainable records

Manufacturing quality

Manufactured to the highest quality control standard - QA system ISO 9001 2015 approved.

Spare parts

CE marked to PED 2014/68/EU

Fluiseal drybreak couplings applications:

- Road tanker loading and unloading

- Rail tanker loading and unloading

- Supply vessel to drilling rig

- Process product transfer.

Typical products handled include: Liquefied gases: LPG, butane, propane, propylene

- Oils: crude, diesel, fuel oils, Jet A1

- Chemicals: ammonia, methanol, aromatics, ethylene & propylene, VCM, alcohols & acids, refrigerants, forane

- Speciality: hydraulic oils, inks, paints, solvents, locomotive fuelling, helicopter fuelling, aircraft de-icing fluids.

- Sizes

2″, 3″ and 4″ or metric equivalents. - Main body construction

Standard material stainless steel 316. - Connections

Threaded and flanged to most standards including ANSI, BS, DIN, ISO and JIS. - Seals

Viton®, Buna, PTFE, Polyurethane, Kalrez®, Chemraz®, others on request. All trademarks acknowledged. - Design

Coupling designed for bi-directional flow. - Temperature range

-50˚C to 100˚C. - Pressure tested

Pressure tested to 34bar.

Q: What is a drybreak coupling?

A: A drybreak coupling usually comprises a female (hose end) fitting and a male (tanker fitting) that are connected/disconnected on a regular basis to form a liquid and pressure tight coupling. Drybreak couplings generally have a valve arrangement that shuts down the liquid flow prior to the disconnection of the male and female couplings. More sophisticated drybreak couplings such as the Alpha Fluiseal are fully interlocked to close down the product flow prior to coupling disconnection.

Enquire Now

To discuss your project, contact one of our team today.

- 1 Brindley Road, South West Industrial Estate, Peterlee. Co.Durham. SR8 2LT

- +44 (0) 191 518 1555

- sales@alphaprocess.co.uk